Press Release

The hub of CLT press releases

Dongwon Global Terminal (DGT) announced opening the first

fully automated terminal in South Korea on 5th April. DGT, the 2nd

to 5th operation phase of the west container harbor in Busan New

Port, is evaluated as a terminal that has set milestones for terminal logistics

history in South Korea by applying domestic technology in various automation

equipment and operation systems. CyberLogitec’s efforts as an IT solution provider,

such as terminal operation systems, are helping to success in DGT

implementation. As a terminal logistics specialized IT solution provider,

CyberLogitec has proven its path domestically and globally, once again

demonstrating the technology in the DGT case.

OPUS Terminal, seize the efficiency and safety

DGT has introduced rare and cutting-edge equipment like AGV(Automated Guided Vehicle), ARMG(Automated Rail Mounted Gantry) and DTQC(Double Trolley Quay Crane); hence, the integrated control technology was required for the equipment.

CyberLogitec has more than 8 implementation references of

Terminal Operation System(TOS) in Automated Terminals both domestic and global.

The implementation references include horizontal and vertical types, and

recently, the world’s first U-Type (Type that supports a side loading method in

which AGV enters the block in vertical-type) fully automated terminal case was

added to the reference list.

Unlike other terminals, a fully automated terminal

applies unmanned equipment such as AGVs, Double Trolley Quay Cranes and others.

To operate the equipment smoothly, an optimal work plan considering each

equipment’s feature and workflow and the development of a solution capable of

being controlled thoroughly are needed.

DGT applies OPUS Terminal Enterprise as a terminal

operation system, Terminal Logistics Controller(TLC) which makes each piece equipment

capable of operating optimally, and OPUS

DigiPort’s IoT platform & data center for data integration management. By

applying organically connecting OPUS Terminal and each solution and module to

the entire terminal, CyberLogitec received an evaluation that achieved

automation efficiency, safety, and productivity as well.

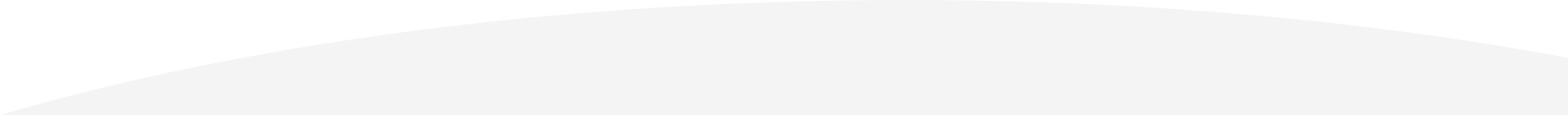

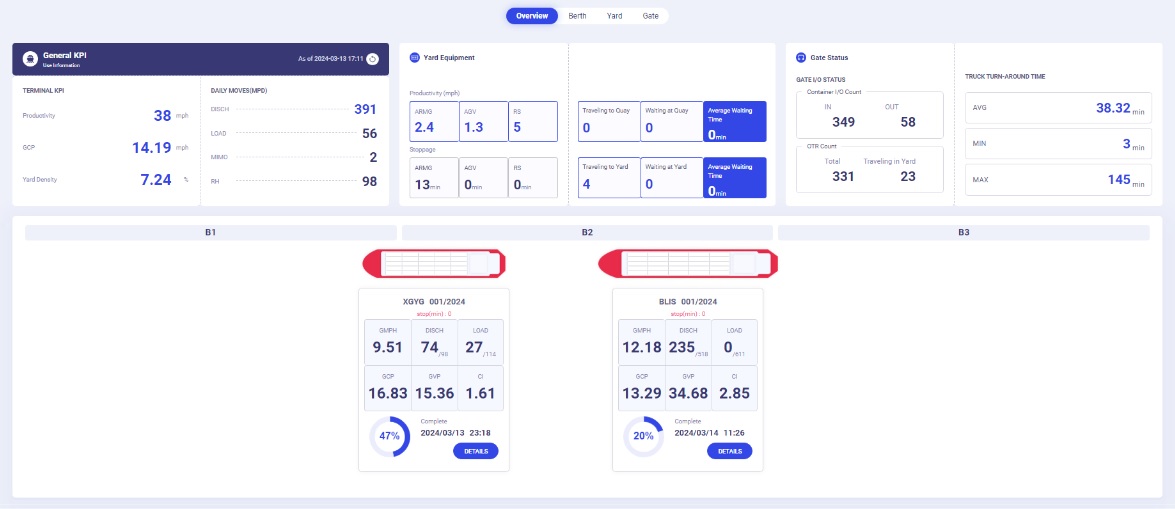

△OPUS DigiPort’s dashboard which applied to DGT. You can see the real-time

terminal status information.

Work optimization implementation by real-time data management

DGT was the first in South Korea to introduce the Double Trolley Quay

Trolley(DTQC.).

DTQC is the equipment for loading and unloading containers to and from

container vessels (sea-side) and harbors (land-side). The existing equipment is

a single trolley that moves between the vessel and land, yet a double trolley

can process more output by two trolleys, which are located one on the vessel

and the other one on the land, associated with the platform. Generally, double

trolleys are known to improve efficiency by 15% compared to single trolleys.

CyberLogitec applied the operation solution for automation implementation to

DTQC. Utilization of the implementation gives the crane the remote-control

capability with monitoring. Hence it could get a wide field view as well as a safety

accident prevention effect.

The importance of stable data processing capability cannot be overstated

when it comes to operating automation equipment smoothly. The equipment

generates a large amount of data every moment, and managing and judging job

orders 24/7 based on this data could easily overload the operation system and

cause errors. Therefore, the establishment of an effective data relay and data

processing method is not just a requirement, but a necessity to ensure the

stability in system operation.

CyberLogitec utilized an IoT platform to relay the various types of data

from the automation equipment ECS(Equipment Controller System), RFID installed

in the terminal and vehicles passing the terminal gate, and then connecting

interface. Due to the applied installation, the DGT operation

system instructs optimal job orders through real-time container and vehicle

location tracking, estimation of the vehicle’s arrival time at the block, and

weight value setting as per the types of work in the terminal.

△OPUS DigiPort’s dashboard which applied to DGT. You can see the real-time

terminal status information.

OPUS Terminal, which is applied in DGT as an operation

system presented by CyberLogitec, prepares work plans based on collected

information in advance, including EDI, assigns the equipment to use, and then

manages overall operation to allocate the work on a real-time basis. At this

time, prevention of equipment collision, interference, deadlock (Condition in

which the equipment is standing still until another equipment to complete the

work) is basic.

CyberLogitec plans to deliver perfect support

for the operation of DGT and, based on its advanced technology, contribute to

the successful implementation of terminal automation projects both domestically

and globally.

Source : Korea Logistics News (https://www.klnews.co.kr) / 2024. 5. 27